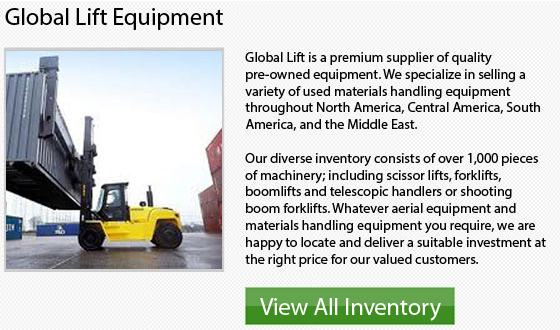

Used Caterpillar Forklifts - Inventory Kansas

To be able to guarantee safety and productivity, your equipment must be maintained whether it is a used forklift or a new forklift. Careless forklift operation could result in added expenses due to abuse and damage. There are easy ways to identify operator practices that indirectly contribute to expenses associated to the improper operation of Caterpillar forklifts or lift trucks. The tips below would truly help you lower operating expenses while ensuring a long life for your equipment.

Causes Of Forklift And Facility Damage

Wrong Forklifts. Selecting the right lift truck equipment for the application is vital for safe and efficient forklift performance. One of the most common mistakes is using the wrong type of forklift or alternatives for the particular job. Equipment can suffer premature wear and tear. Parts could be subject to failure. Check that the lift truck is fitted with the right tires and that they are not worn.

Improper Forklift Operating Practices. A common cause of impact damage is incorrect forklift operating practices. Damage to product, equipment or facilities may occur while navigating around products. A congested work area lends itself to impacts. For instance, pushing pallets, called "Bulldozing", could wear tires and damage the transmission.

Unsafe Forklift Speeding and Lifting. Incorrect lifting practices could lead to personal injury and equipment damage. Common errors comprise lifting too high and traveling very fast. A load which is very heavy could cause the forklift to tip over. The operator must make sure that the forks are level.

Poor Floor Conditions. The most common cause of forklift damage are obstructions and debris on the floor. If twine, wood, plastic or banding gets into the engine compartment, the cooling system can be compromised. The result can be engine failure or even fire.

Axle or radiator damage is one more common consequence of driving over debris.

Caterpillar TH360B

The model TH360B built by Caterpillar is a four wheel drive lift truck in Kansas. This version has a diesel powered engine and has the ability to lift a maximum of 7000 pounds up to...

Caterpillar P26500

The lifting ability of the Caterpillar P26500 in Kansas is 26500 pounds. Some of the other notable features of the P26500 are: 168 ft lifting height and a diesel engine.

Caterpillar DP50

The model DP50 built by the company Caterpillar is a two wheel drive lift truck in Kansas. This unit has a diesel powered engine and has the ability to lift a maximum of 10000 lbs...

Caterpillar V330

The lifting capacity of the Caterpillar V330 in Kansas is 33000 pounds. Some of the other notable features of the V330 are: 168 ft lifting height and a diesel engine.

Caterpillar P33000

The P33000 model produced by Caterpillar is a two wheel drive lift truck in Kansas. This unit has a diesel powered engine and has the ability to lift a maximum of 33000 lbs up to...

Caterpillar TH560B

The lifting ability of the Caterpillar TH560B in Kansas is 11000 pounds. Some of the other notable features of the TH560B are: 44 feet lifting height and a diesel engine.

Caterpillar Telehandler Forklifts Kansas

A telescopic handler is similar to a forklift. It possesses a single telescopic boom that extends both forwards and upwards from the truck, and a counterweight within the back. It functions more like a crane...

Caterpillar Propane Forklifts Kansas

Utilizing both electric and internal combustion (IC) trucks have different disadvantages and advantages.

Electric engines need much less maintenance, and hence they cost less to maintain over their life span. The battery should last five...

Caterpillar Empty Container Handlers Kansas

Kinds of forklifts:

A main consideration when buying a forklift is whether to go with electric, hybrid or internal combustion. Each and every technology has its advantages and disadvantages. It is important to distinguish one...